Service Life of Plastic-Steel Sheet Piles

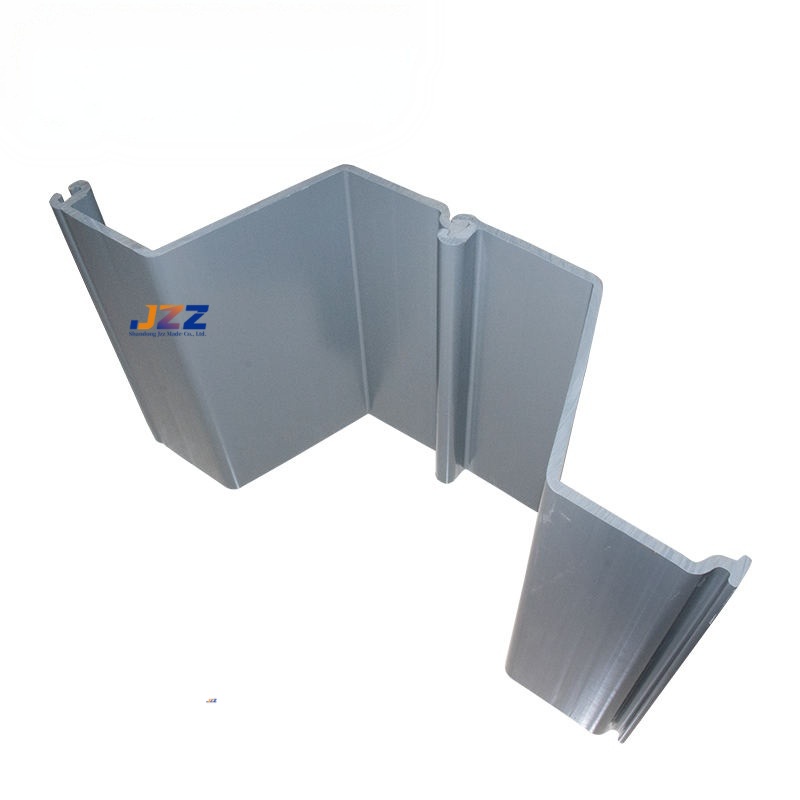

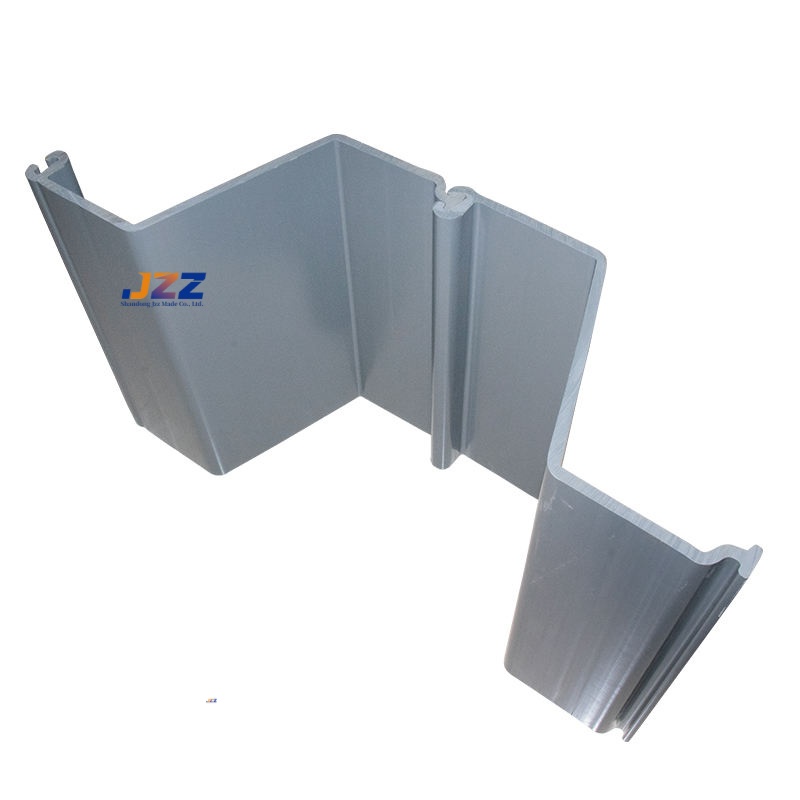

1. Material and Design Factors

Plastic Layer (e.g., HDPE/PVC): Highly corrosion-resistant with excellent performance in acidic, alkaline, and salt spray environments, offering a lifespan exceeding 30 years.

Steel Core Layer: If the plastic layer remains intact, it effectively blocks corrosion, extending the steel’s lifespan accordingly. If the plastic layer is damaged, the steel’s corrosion rate accelerates.

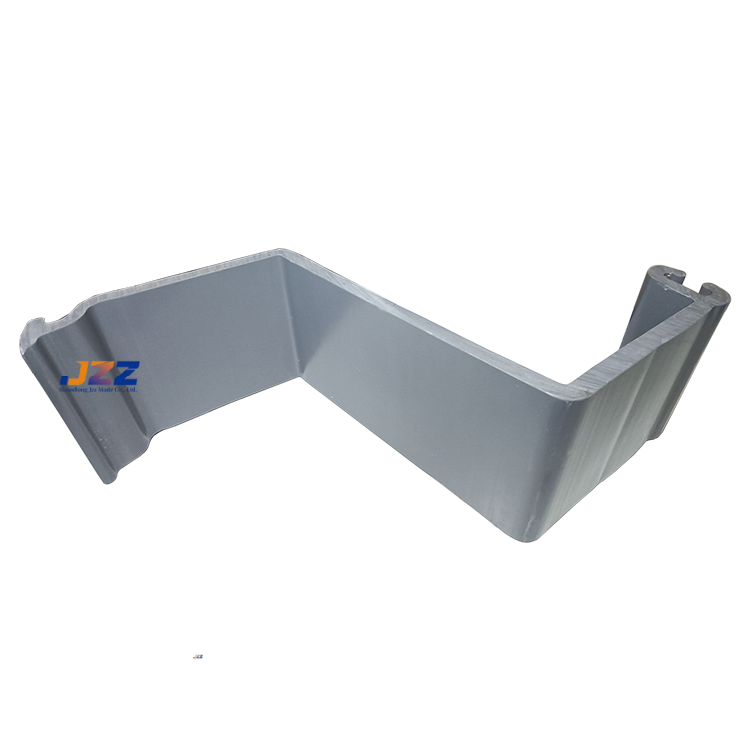

2. Environmental Factors – Mild Environments (e.g., freshwater waterways, low-corrosive soils): Service life may approach 50 years. – Harsh Environments (e.g., seawater, highly acidic/alkaline soils): Service life may shorten to 20-30 years, requiring regular inspection and maintenance.

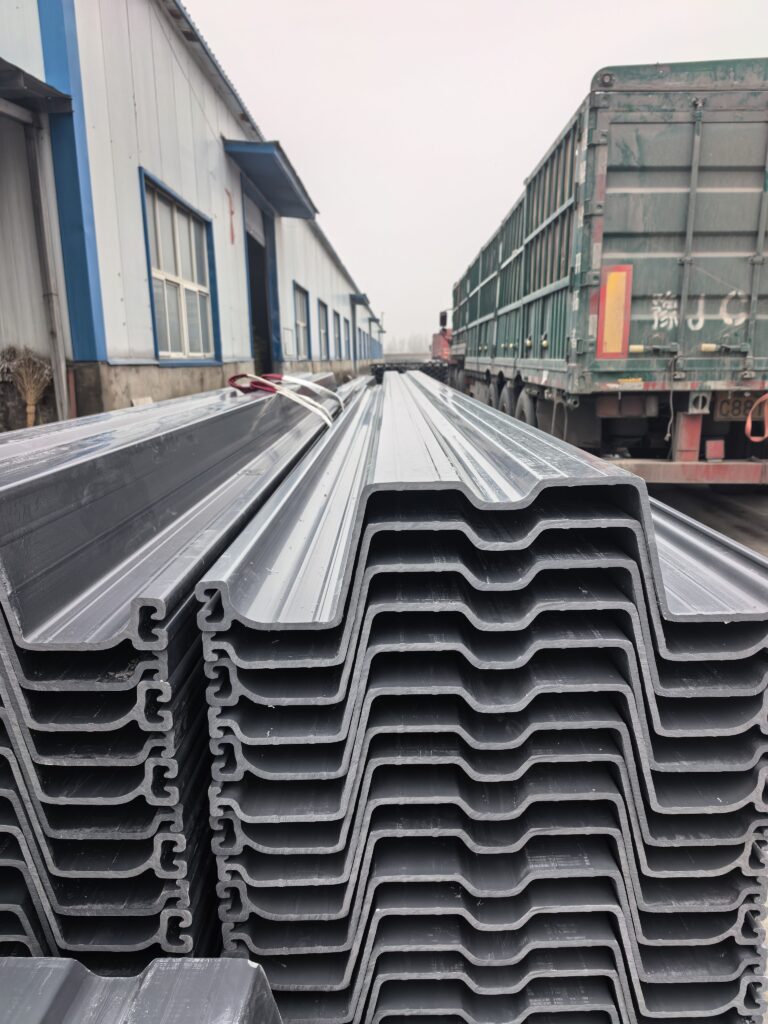

3. Construction and Maintenance • Installation Protection: Ensuring tight interlocking connections and avoiding mechanical damage extends service life. • Regular Maintenance: Inspecting for plastic layer damage or rust spots and promptly repairing them significantly enhances service duration. 4. Industry Case References Some project cases demonstrate that high-quality plastic-steel sheet piles maintain full functionality after over 40 years of service in municipal engineering projects.