The core advantages of plastic steel sheet piles compared to other pile types (traditional steel sheet piles, concrete piles, etc.)

1. Superior environmental performance: Unlike traditional steel sheet piles with high energy consumption during production and concrete piles that are difficult to recycle after disposal, this product utilizes a blend of non-toxic polymer materials and recycled PVC. Manufactured through a single extrusion process with zero pollution and no harmful components, it does not contaminate soil or water during support operations. After decommissioning, it is 100% recyclable, eliminating construction waste throughout its entire lifecycle. This fully complies with green construction acceptance standards and is particularly suitable for foundation pit projects in urban core areas.

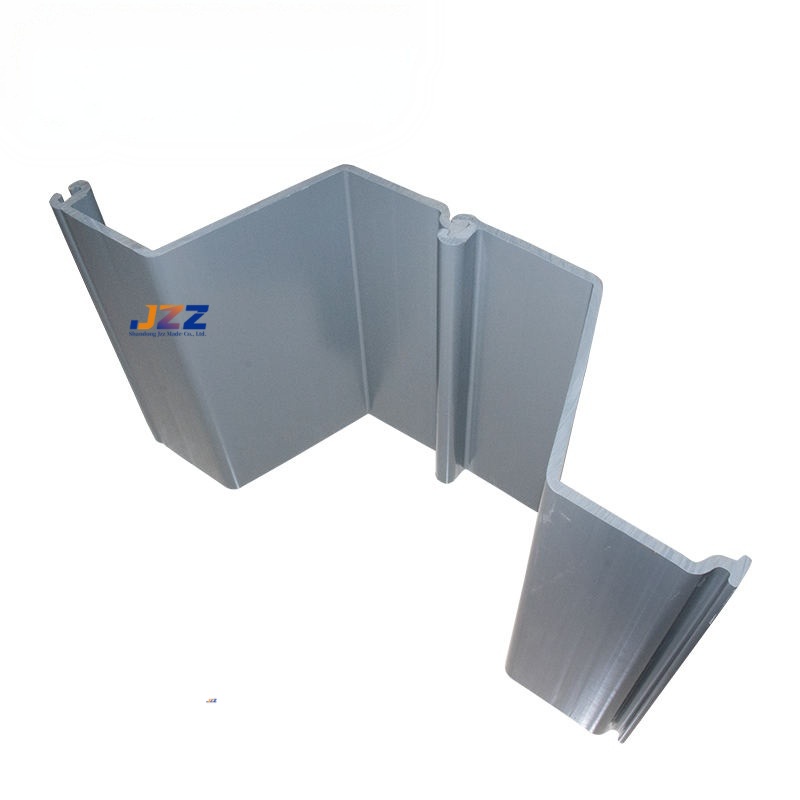

2. Superior Corrosion Resistance and Longevity: Traditional steel sheet piles are prone to corrosion from moist soil and groundwater, leading to strength degradation; concrete piles weather and spall in acidic or alkaline environments. Our product’s “external plastic corrosion protection + internal steel load-bearing” structure resists damp soil, groundwater, and mild acid/alkali corrosion. It maintains stable performance between -40°C and 60°C, boasts a long service life, and requires no additional anti-corrosion maintenance during operation, significantly reducing operational costs and safety risks.

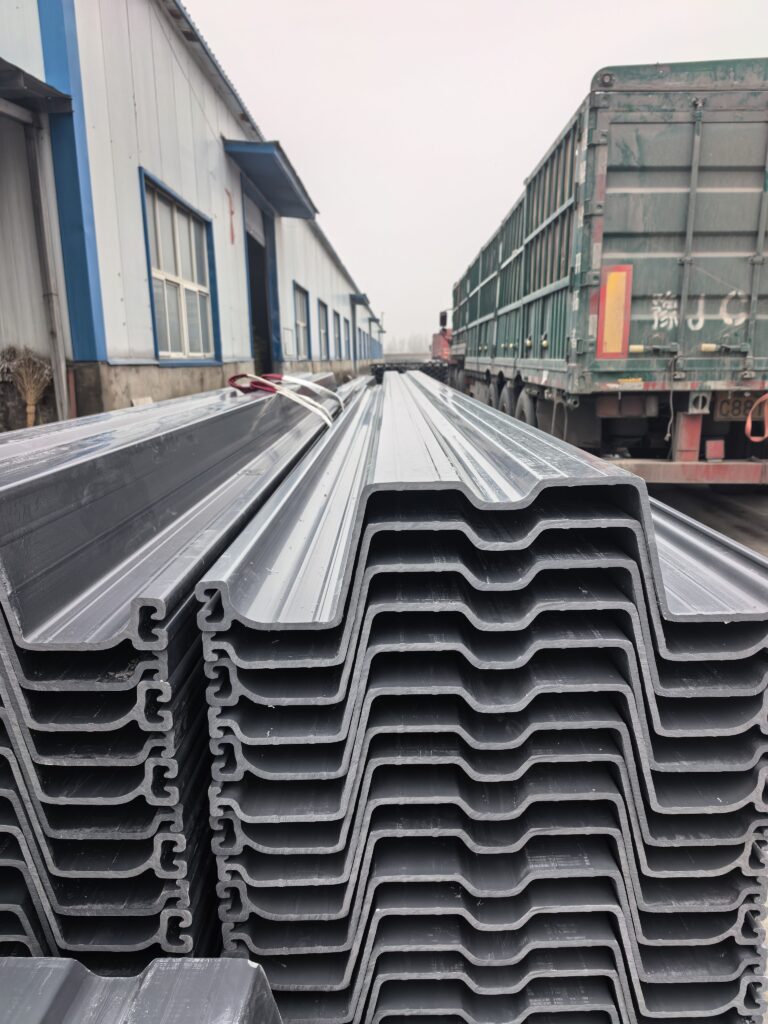

3. Enhanced Construction Efficiency and Versatility: Concrete piles require lengthy pouring cycles and are difficult to adjust post-curing. Traditional steel sheet piles are heavy (this product weighs only 1/5 to 1/8 as much, ≤18kg per linear meter) and rely on large lifting equipment, making them unsuitable for confined spaces. Short piles can be manually deployed, while long piles require only small vibratory pile drivers for installation, achieving an average daily construction rate of 100 meters and reducing project duration by over 40%. The snap-fit connection ensures excellent watertightness, seamlessly adapting to irregular excavation contours while balancing efficiency and sealing integrity.

4. More Controllable Overall Costs: Compared to traditional pile types, this product not only reduces raw material, transportation, and hoisting costs but also eliminates the need for post-construction anti-corrosion maintenance and minimizes secondary construction losses. It achieves cost optimization throughout the entire lifecycle from construction to service, while balancing safety and ecological value, offering superior overall cost-effectiveness.