Environmental performance is the core competitive advantage of the product. Using PVC-U as the base material combined with eco-friendly modifiers, it embodies green principles throughout its entire lifecycle. Production energy consumption is only one-third that of traditional steel, significantly reducing carbon emissions. During use, there are no corrosive residues or heavy metal pollution, making it suitable for ecologically sensitive projects like river restoration and wetland conservation. After decommissioning, it is 100% recyclable, completely resolving the pain points of traditional steel sheet piles being difficult to recycle and polluting the environment. Among these, recyclable PVC plastic steel sheet piles are the mainstream category in the market and a benchmark choice for green projects.

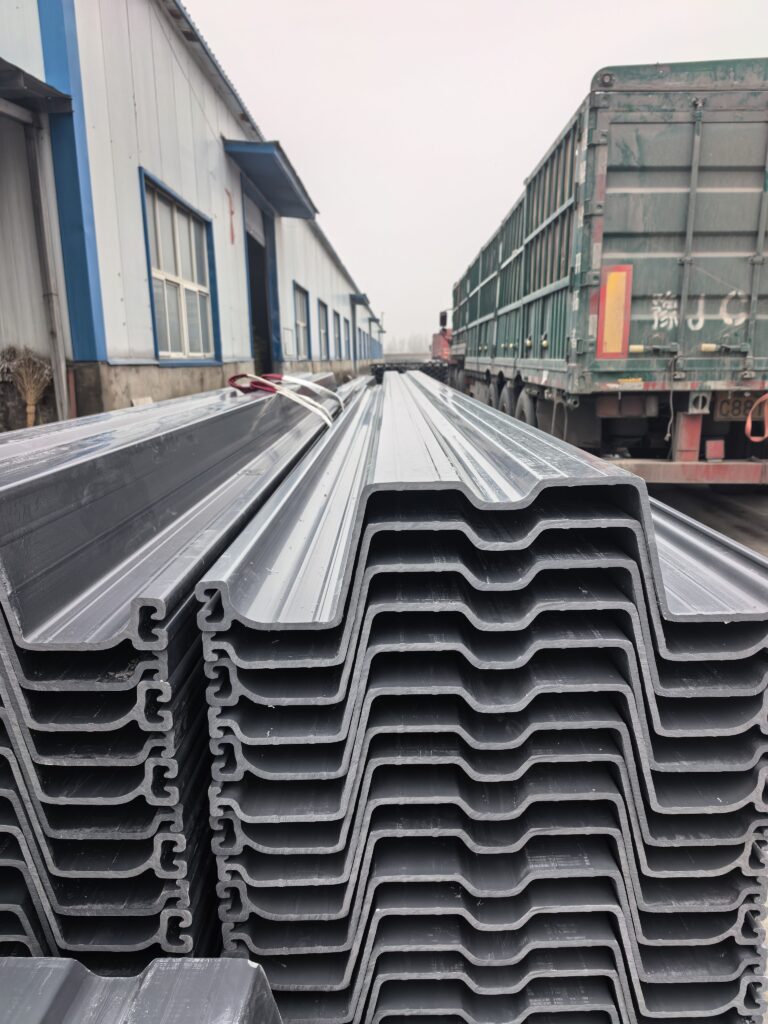

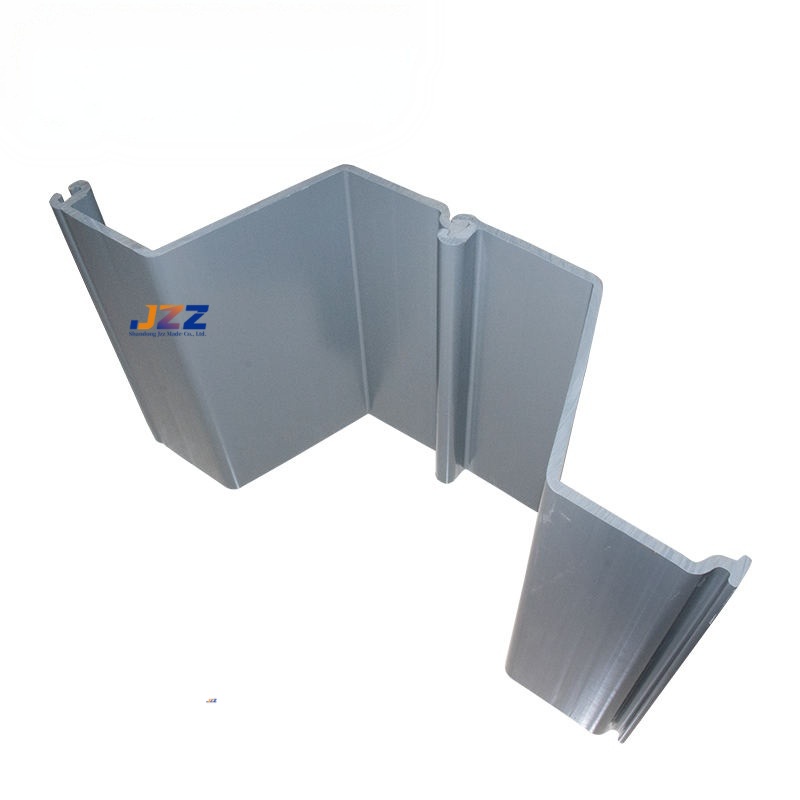

Through triple innovation in materials, design, and manufacturing, the product achieves a perfect balance of lightweight construction and high strength, shattering the misconception that “environmental friendliness equates to compromised performance.” Material-wise, glass fiber modification boosts bending strength by 40%-60%, while high-end carbon fiber composite variants exceed 150MPa in bending strength. They exhibit outstanding corrosion resistance and aging resistance, with a service life exceeding 30 years in complex conditions—eliminating the need for periodic anti-corrosion maintenance. Design incorporates M-shaped and Z-shaped cross-sections with interlocking profiles, enhancing overall support and leak resistance while preserving ecological adaptation space. Manufacturing employs single-extrusion molding technology to ensure dimensional accuracy (±0.5mm tolerance) and batch consistency, meeting large-scale project procurement demands.

Its lightweight nature delivers significant construction advantages: weighing 60% less than traditional steel sheet piles (only 1/4 to 1/3 the weight), it eliminates the need for heavy lifting equipment. Rapid deployment is achievable through manual labor supplemented by small machinery, making it suitable for confined spaces, complex terrains, and emergency projects. In temporary cofferdam projects, this product reduces construction time by over 30% and lowers overall costs by 50%, while being recyclable and reusable. Modular design enables customization to meet specific needs. U-shaped and Z-shaped piles respectively suit scenarios of shallow loads on soft soil and deep loads on hard soil, achieving flexible “one-pile-multiple-uses” applications.

The product has evolved from temporary support to permanent structures, with applications spanning the entire infrastructure sector. In temporary applications, its efficiency and rentability make it an ideal choice for short-term projects like foundation excavation and emergency response; In permanent applications, it is widely used in riverbank protection, flood control embankments, and ecological restoration projects. It achieved dual benefits of flood prevention and ecological enhancement in the Suzhou River ecological restoration project, while landmark projects like the Hangzhou Asian Games further validate its reliable quality. Simultaneously, its lightweight and eco-friendly advantages align with emerging market demands in Southeast Asia, continuously unlocking export potential.

Intelligent construction adaptation and refined industry standards ensure seamless product implementation. Equipped with 3D laser scanning positioning (±2cm accuracy) and intelligent hydraulic hammers, it enables precise construction control. Pre-installed planting slots at the pile top facilitate “green slope protection,” fostering symbiosis between engineering and nature. The product complies with national standards including T/CWEA 18-2023 and GB/T 19472.2, ensuring regulatory adherence and steadily growing industry recognition.

As a representative material of domestic technological breakthroughs, plastic steel sheet piles will evolve toward high-end, diversified, and intelligent upgrades. Through material composites, they will expand adaptability for premium applications, extending into building main structures. Leveraging smart technology for full-process construction control, they will continuously lead green transformation in engineering, becoming a core competitive material in the global infrastructure market.