Product Features: The Perfect Combination of Lightweight and Zero Maintenance

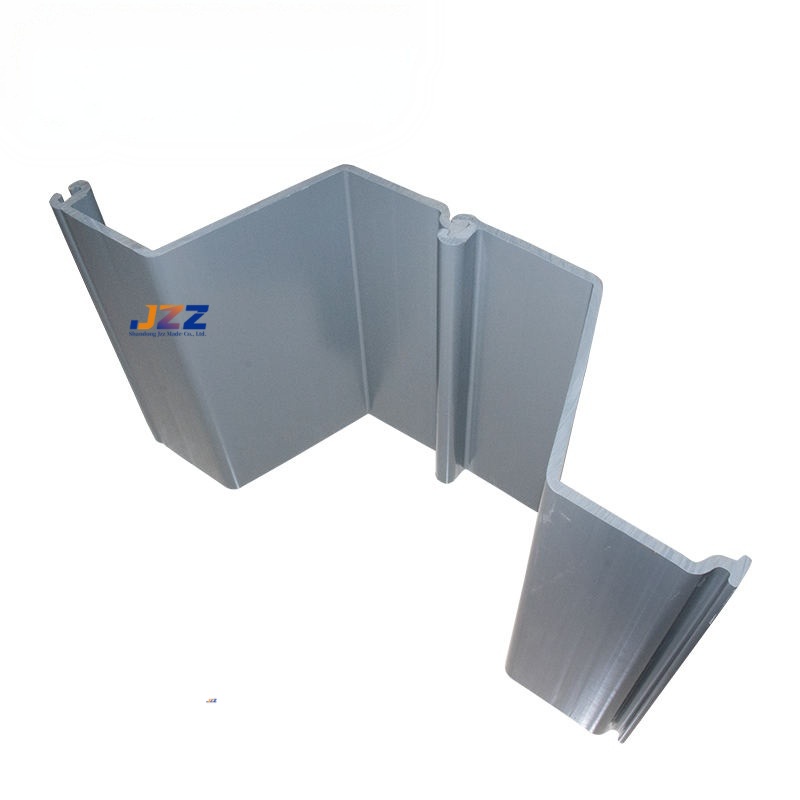

The core advantage of plastic steel sheet piles lies in their lightweight design and zero-maintenance characteristics. Manufactured using eco-friendly polymer-reinforced composite materials with additives integrated through a single extrusion molding process, these sheet piles weigh only one-eighth of traditional materials. This significantly reduces transportation and installation costs while maintaining high strength and durability. With tensile strength reaching 43-44 MPa and flexural strength at 63-71 MPa, they withstand intense water currents in navigation channels and vessel berthing pressures, ensuring structural integrity. Furthermore, their exceptional corrosion resistance prevents aging or damage in prolonged water exposure, virtually eliminating post-installation maintenance and delivering on the promise of “worry-free shoring.” The ecological pore design further enhances its environmental attributes by providing habitats for aquatic life and promoting ecological balance.

Application Scenario: Outstanding Performance in Waterway Slope Protection

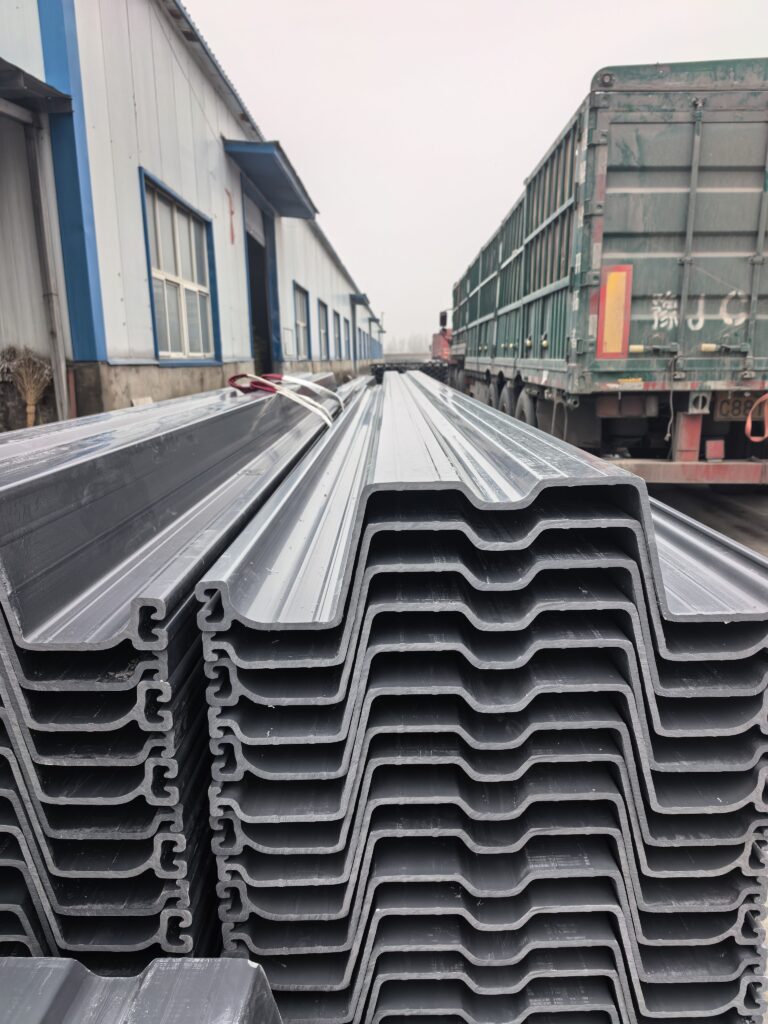

Plastic steel sheet piles demonstrate broad applicability and innovative value in waterway slope protection projects. In waterway revetment scenarios, they form continuous retaining structures that effectively prevent riverbank collapse and soil erosion. Their multi-directional interlocking joints ensure tight pile connections, enhancing overall stability. For instance, in Jiaxing’s waterway upgrade project, plastic-steel sheet piles significantly reduced land occupation and project investment, conserving 1,500-2,250 mu of land per 100 kilometers of waterway and saving 300-450 million yuan in costs. Their lightweight nature simplifies construction processes, enabling efficient deployment even in complex geologies like gravel or sand layers, shortening project timelines and reducing labor requirements. Field tests validated their impact resistance and corrosion tolerance, establishing them as reliable barriers against flood and water erosion.

Construction Advantages: Dual Assurance of Efficiency and Safety

The construction process is another major highlight of plastic steel sheet piles. Their lightweight nature facilitates transportation and installation, requiring only two medium-sized trucks for mechanical transfer, significantly reducing construction footprint and environmental impact. The operation is both efficient and safe, utilizing hydraulic vibratory hammers and pile-driving sleeves for precise driving. Sinking speeds reach 4-7 meters per minute, with a maximum of 12 meters per minute, far exceeding traditional methods. Modular design further streamlines installation steps. Even in challenging terrains like soft soil or steep slopes, waterjet-assisted processing ensures project quality. Compared to traditional methods, plastic steel sheet pile construction not only boosts efficiency but also lowers overall costs, delivering immediate return on investment.

Environmental Sustainability and Aesthetics: Engineering in Harmony with Nature

The eco-friendly design of plastic steel sheet piles extends throughout the material’s lifecycle—from production and installation to usage. The material itself contains no harmful substances like lead or plasticizers, posing no pollution risks to water or soil, aligning with green construction principles. Its recyclability enhances sustainability by reducing resource consumption. Aesthetically, the ecological perforation design supports aquatic plant growth, allowing revetment structures to blend seamlessly into natural environments and enhance landscape appeal. For instance, in river management projects, the double-layer revetment structure of plastic steel sheet piles, combined with slope greening, establishes an ecological protection system. This enhances structural stability while adding natural beauty to urban and rural projects.

Future Outlook: Pioneering New Trends in Green Slope Protection

With growing environmental awareness and technological advancements, plastic steel sheet piles hold vast application potential. They are not only an ideal choice for current waterway slope protection but also represent the future direction of green construction. From urban waterways to rural water conservancy projects, plastic steel sheet piles—with their lightweight, zero-maintenance, and eco-friendly characteristics—continue to create more sustainable living environments for humanity, driving the industry toward innovation and ecological transformation. Their exceptional performance and innovative design are propelling waterway engineering into a new era of efficiency and environmental stewardship.