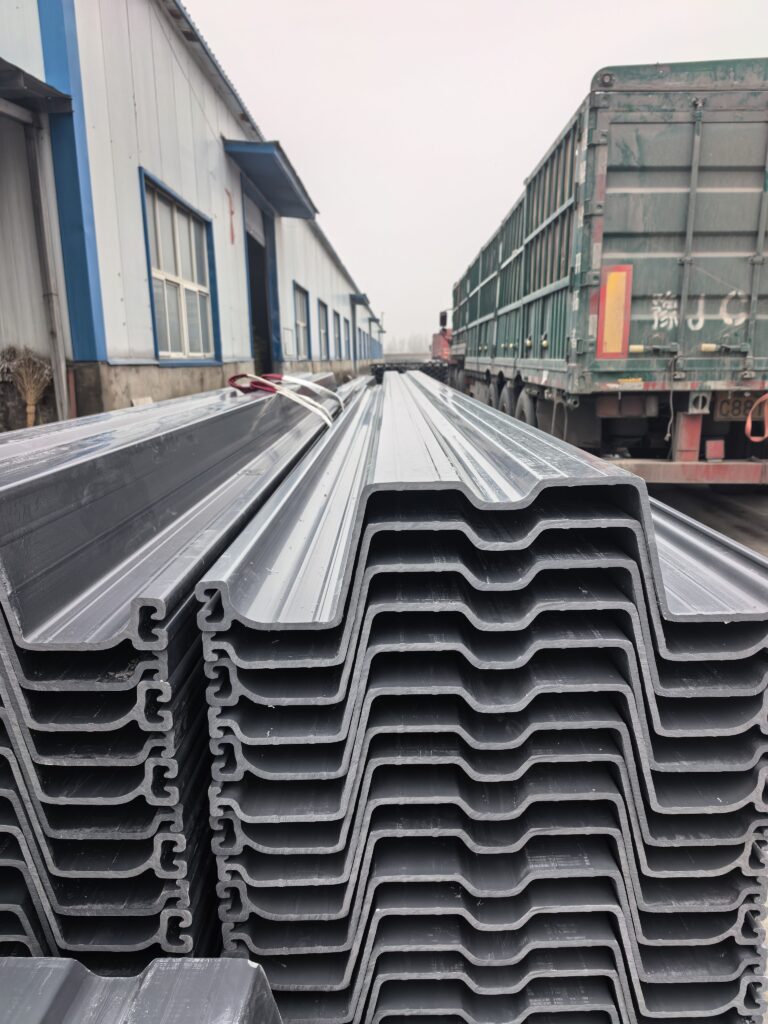

Plastic steel sheet piles are a new type of engineering material centered on polymer composites. With advantages such as environmental friendliness, corrosion resistance, and high efficiency, they serve as an ideal alternative to traditional steel and timber piles, finding widespread application across diverse construction projects.

Core Properties

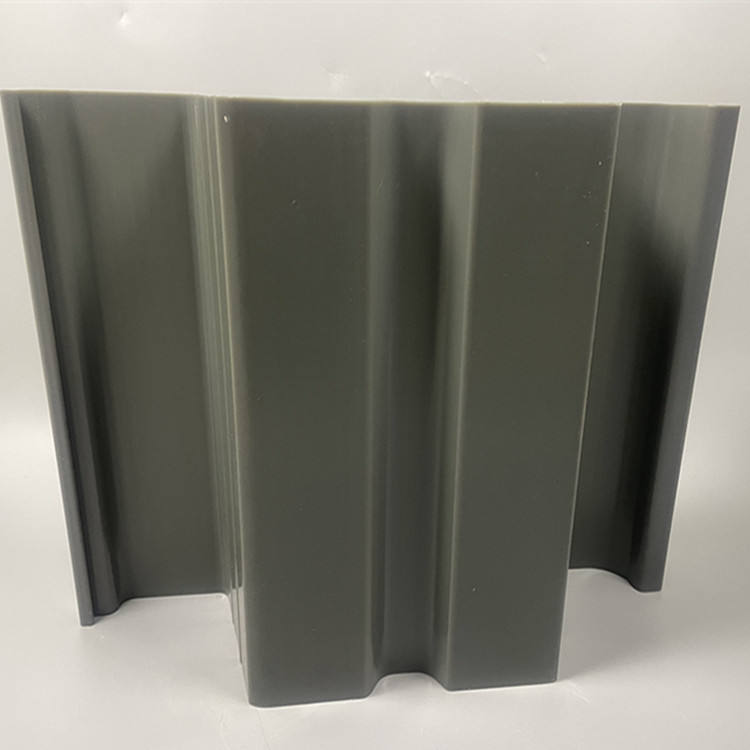

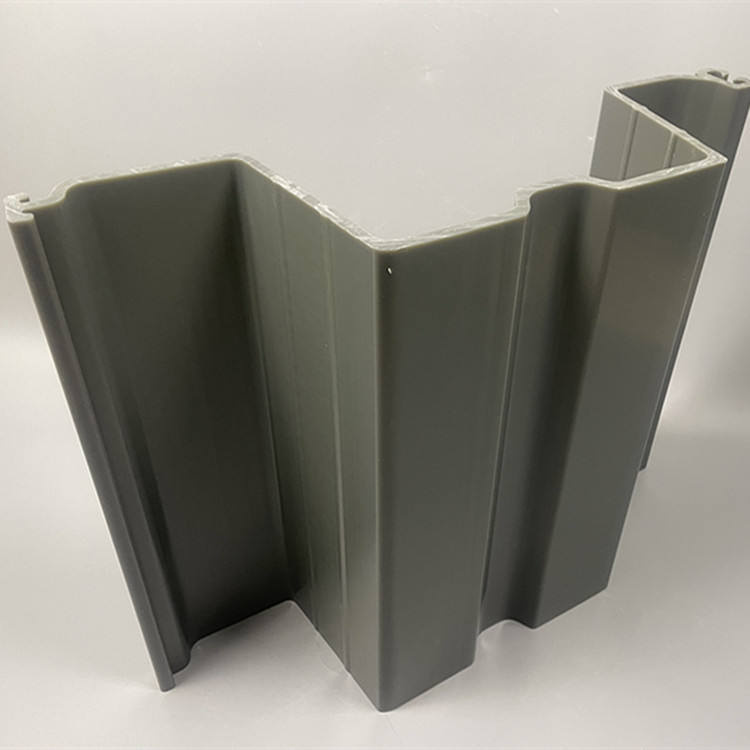

The core substrate consists of high-density polyethylene (HDPE) and polypropylene (PP), reinforced with additives for UV resistance, anti-aging properties, and enhanced modification, formed through extrusion molding.

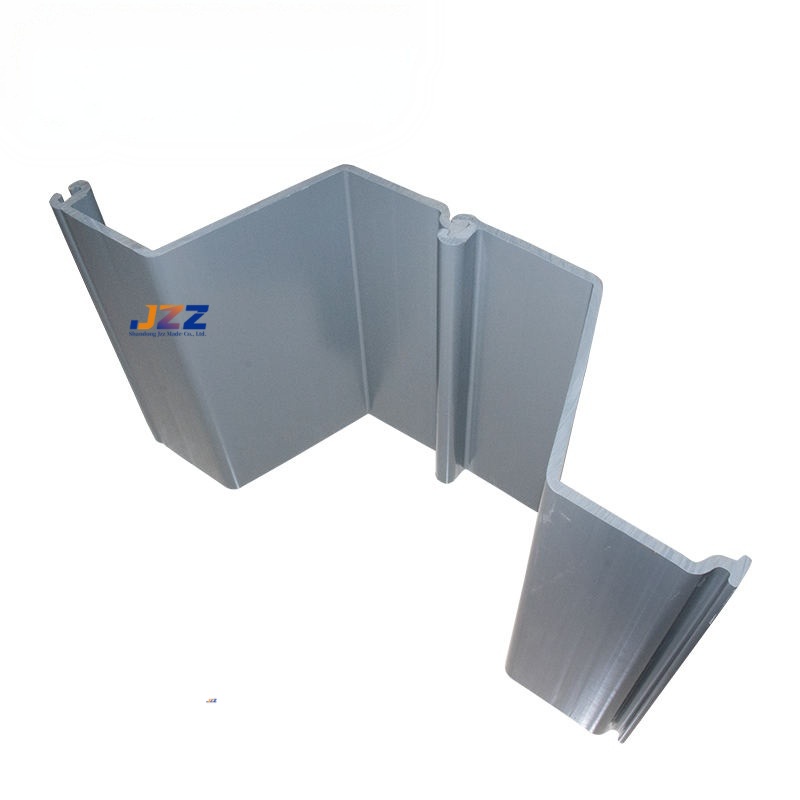

The structure features a high-moment-of-inertia cross-section design, paired with interlocking or tongue-and-groove joints. When assembled, it forms a continuous, sealed support/seepage control system that balances mechanical stability and sealing integrity.

Core Advantages

Corrosion Resistance & Durability: Withstands soil and water environments with pH values ranging from 4 to 10, offering a service life exceeding 50 years without additional anti-corrosion treatment. Suitable for complex natural conditions.

Superior Mechanical Properties: Tensile strength ≥25MPa, flexural modulus ≥800MPa. Combines strength and toughness to effectively withstand earth pressure and water pressure without fracturing or deformation.

Efficient Installation: Weighs only 1/8–1/10 of steel, enabling easy transportation and handling. Requires no welding or cutting; rapid assembly and installation using specialized piling equipment significantly reduces project duration.

Environmentally Friendly & Leak-Proof: Free from harmful substances like lead and plasticizers, causing no pollution to soil or water. Fully recyclable. Interlocking joints with waterstop strips provide outstanding sealing, effectively blocking water leakage.