I. Core Product Highlights (Focus on Three Core Advantages + Interlocking Anti-Seepage)

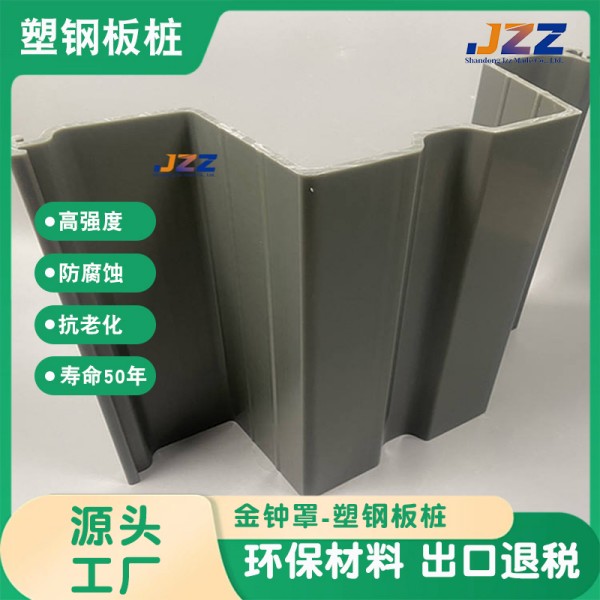

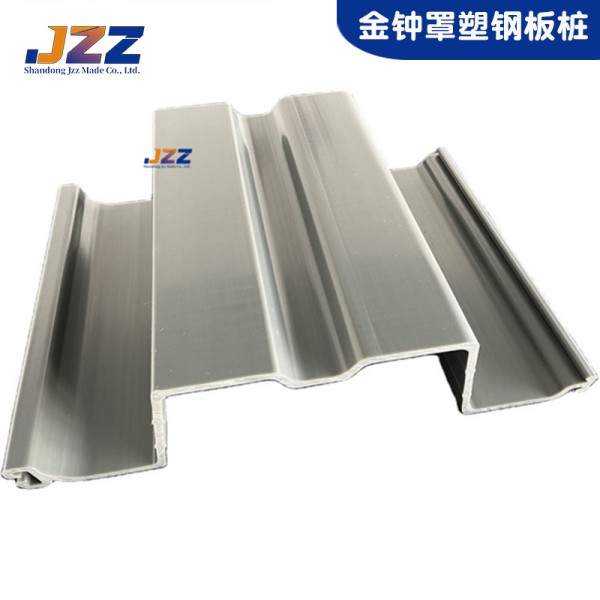

Specifically engineered for complex acidic and alkaline environments, this support material utilizes polymer composite as its base material. Enhanced with fiberglass reinforcement and anti-aging formulations, it is manufactured through a single extrusion molding process. It combines three core advantages: corrosion resistance, maintenance-free operation, and interlocking anti-seepage, making it perfectly suited for demanding support applications in chemical plants, sewage treatment facilities, coastal saline-alkali soils, and similar harsh conditions.

1. Exceptional Corrosion and Acid/Alkali Resistance: Utilizing eco-friendly polymer-reinforced materials, it withstands erosion from pH 3.0-11.0 acidic/alkaline media. Unaffected by harsh environments like saltwater or chemical reagents, the material remains stable without aging, cracking, or rusting. Compared to traditional steel sheet piles with short lifespans in acidic/alkaline settings, it delivers over 50 years of service life.

2. Lifetime Maintenance-Free: The material’s inherent chemical stability and structural durability eliminate the need for additional anti-corrosion treatments or periodic maintenance. This completely eliminates long-term operational costs, offering significantly higher cost-effectiveness over traditional support materials throughout its entire lifecycle. It is particularly suitable for projects involving prolonged immersion in acidic or alkaline water bodies.

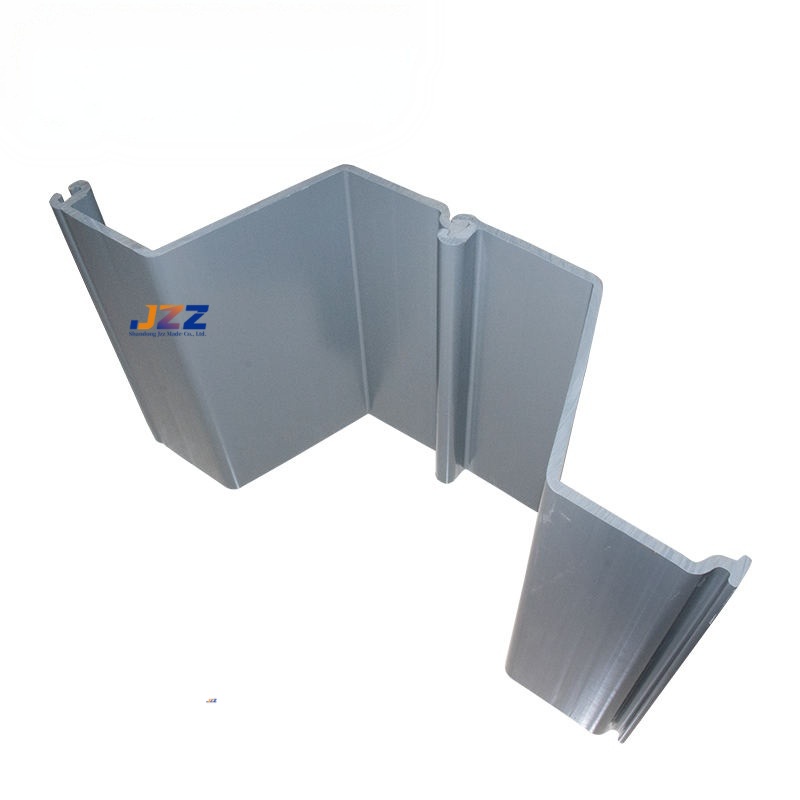

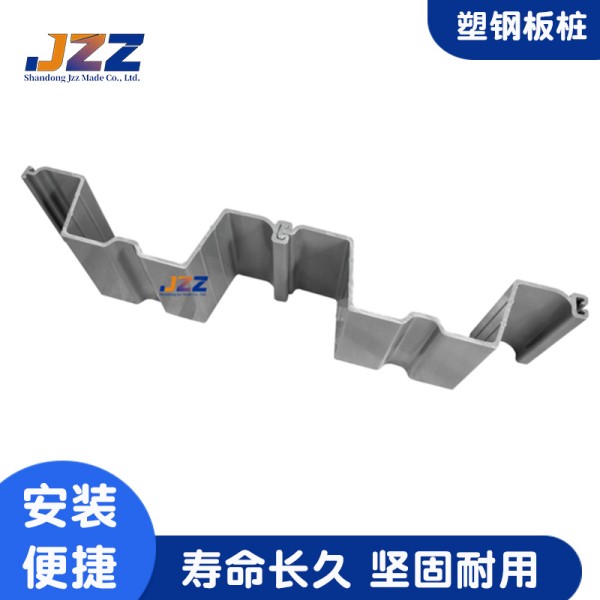

3. Interlocking Waterproof Design: Featuring a CT-type interlocking profile with integrated rubber seals, the panels form a continuous, watertight retaining wall upon assembly. Watertightness testing achieves ≤0.1L/(m·d), effectively blocking acid/alkali water penetration. With interlock shear strength ≥15kN/m, connections remain secure and stable. offering superior lateral bending and impact resistance that meets Class II foundation pit support safety requirements.

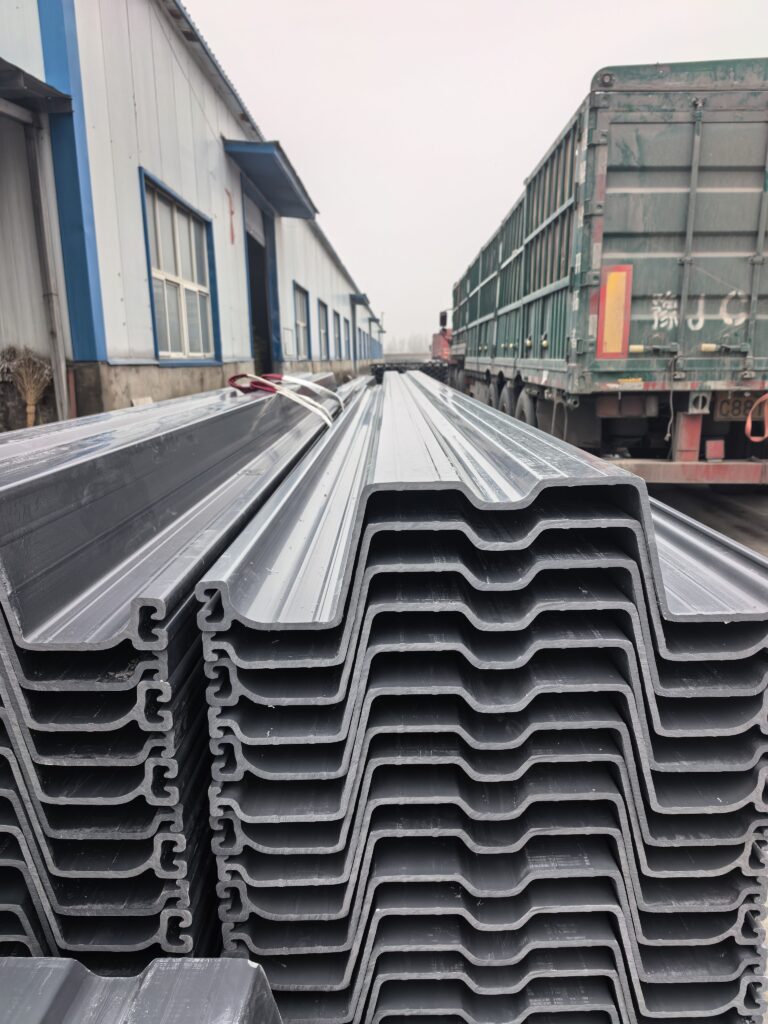

4. Lightweight and Easy Installation: Weighing ≤18kg per linear meter—only 1/8 the weight of traditional steel sheet piles—it requires no heavy lifting equipment. Efficient installation is achieved using hydraulic vibratory pile drivers. Interlocking assembly resembles building blocks, with sinking speeds reaching 4-7 meters per minute, significantly reducing project duration. Suitable for complex geologies including clay, sand, and gravel layers, it can operate even in rainy conditions.

II. Precise Application Scenarios (Tailored for Acidic/Alkaline Environments)

1. Chemical Industrial Parks: Used for foundation pit support and impermeability in chemical raw material storage areas and acid/alkali wastewater treatment tanks. Withstands high-concentration acid/alkali corrosion. Interlocking impermeable design prevents pollutant leakage and diffusion. Maintenance-free characteristics reduce operational burden.

2. Wastewater Treatment Plants: Suitable for support structures in biochemical tanks, sedimentation tanks, and sludge treatment areas. Corrosion-resistant materials withstand acid/alkali substances and microbial corrosion in wastewater. Interlocking sealed structures prevent sewage infiltration, eliminating the need for periodic anti-corrosion maintenance and ensuring long-term stable operation.

3. Coastal/Saline-Alkali Areas: Suitable for coastal protection, saline-alkali riverbank reinforcement, and harbor wharf support. Resists seawater salt corrosion and saline-alkali soil erosion. Interlocking connections form continuous walls that effectively prevent scouring and leakage, while lightweight design facilitates on-site construction near the sea.

4. Acid/Alkali Tank Storage Areas: Used for foundation pit containment and leak-proof support around large acid/alkali storage tanks. The interlocking structure ensures the integrity and sealing of the retaining wall. Its corrosion-resistant, maintenance-free properties meet the long-term operational demands of storage tanks, eliminating safety hazards caused by material corrosion.

5. Industrial Wastewater Channels: Reinforces banks of industrial wastewater discharge channels and acid/alkali liquid transport ditches. Directly contacts various industrial wastewater types. Interlocking anti-seepage function prevents liquid leakage from contaminating soil and groundwater. Efficient construction minimizes disruption to normal plant operations.

III. Engineering Application Advantages (Compared to Traditional Materials + Actual Value)

Compared to traditional steel sheet piles requiring frequent anti-corrosion maintenance and concrete piles prone to acid/alkali erosion and cracking, this product demonstrates significant advantages in acid/alkali environment projects: First, cost advantage: initial procurement costs are comparable to traditional materials, with zero operational maintenance investment later, reducing total lifecycle costs by over 30%. Second, safety advantages: Dual protection from interlocking anti-seepage and corrosion-resistant properties eliminates risks of acid/alkali leakage and structural damage, meeting Grade II safety requirements for excavation sidewalls. Third, ecological advantages: Utilizes non-toxic, environmentally friendly formulations free of lead and plasticizers, causing no pollution to soil or water bodies. Can incorporate ecological voids to balance support functions with ecological conservation needs.

Case Study: In a wastewater treatment basin support project at a chemical industrial park, this product served as the core support material. Construction proceeded in water without requiring cofferdams, reducing the project timeline by 40% compared to traditional steel sheet piles. Post-installation, no maintenance was required. After three years of monitoring, the structure remained stable with zero leakage, fully meeting the demands of high-concentration acid and alkali wastewater environments.