The installation of plastic steel sheet piles must adhere to the following special requirements to ensure project quality and construction safety:

1. Site Preparation Ground Leveling: Clear the site before installation to ensure the ground is level and free of debris, preventing uneven stress distribution on the sheet piles due to unevenness. Layout and Positioning: Precisely mark the installation positions and axes of the sheet piles according to design drawings, with tolerances controlled within ±10cm.

2. Tool Selection Vibratory Hammers or Static Pressing Equipment: Prioritize high-frequency vibratory hammers (suitable for loose soil layers) or static presses (minimal environmental impact), avoiding direct hammering that could damage pile heads. Guide Frame Assistance: Use guide frames to control verticality and prevent tilting for long piles (>6 meters).

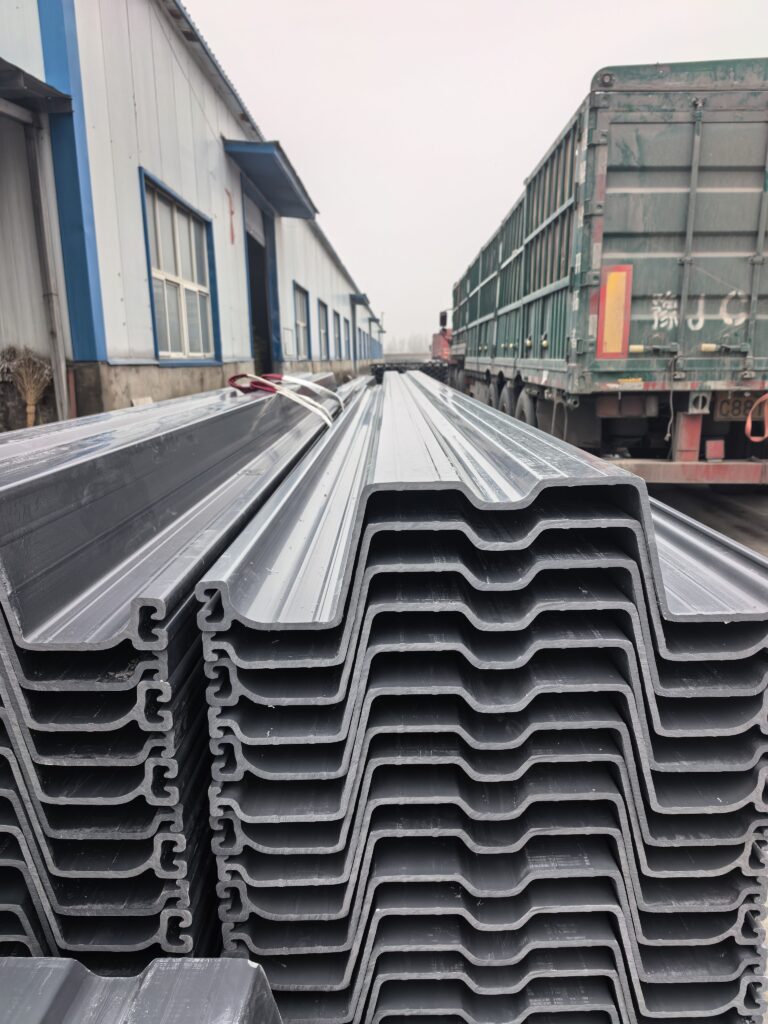

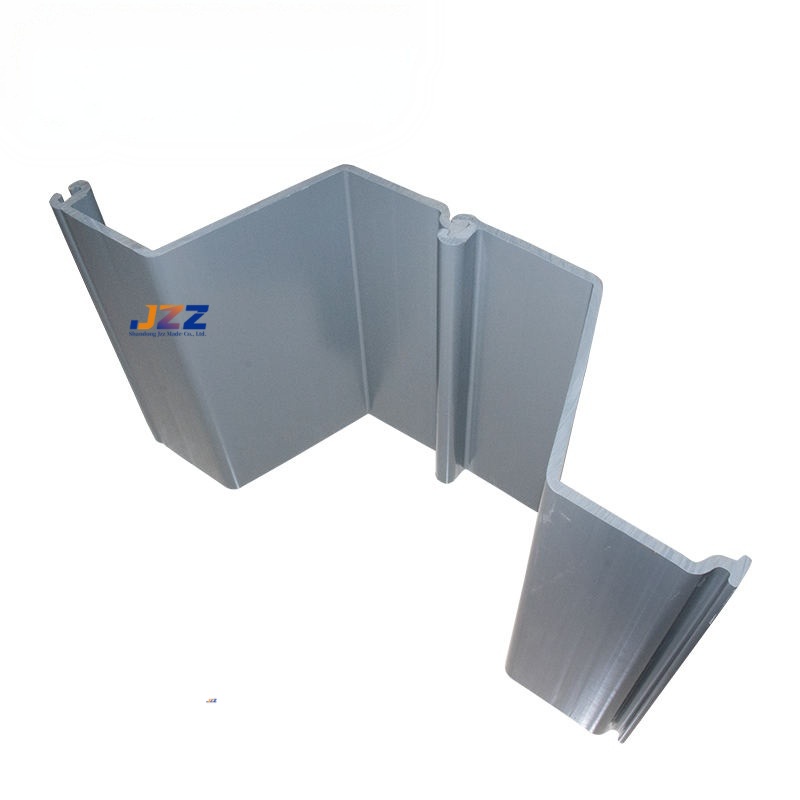

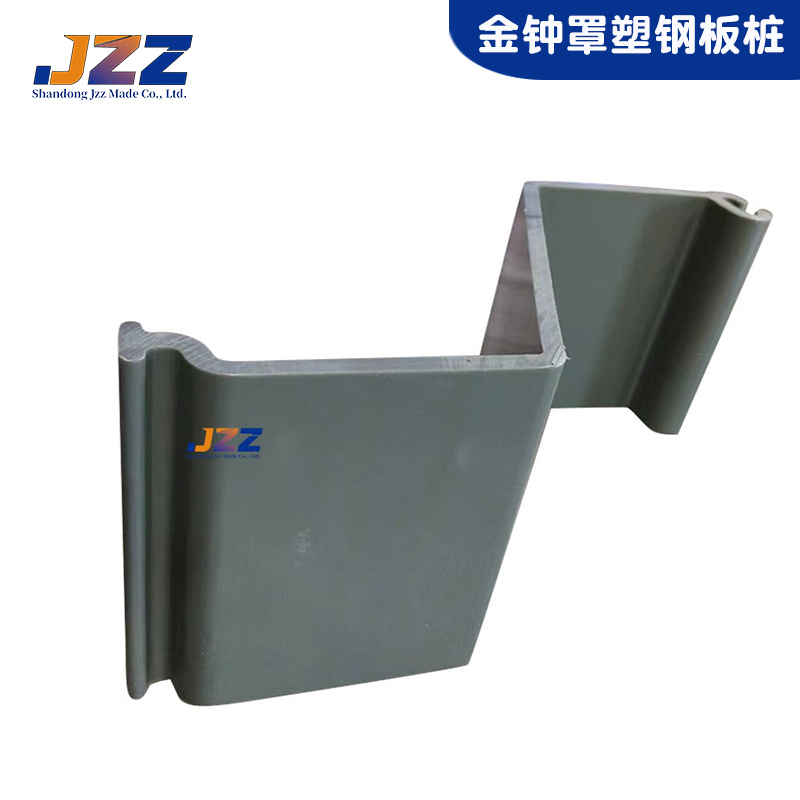

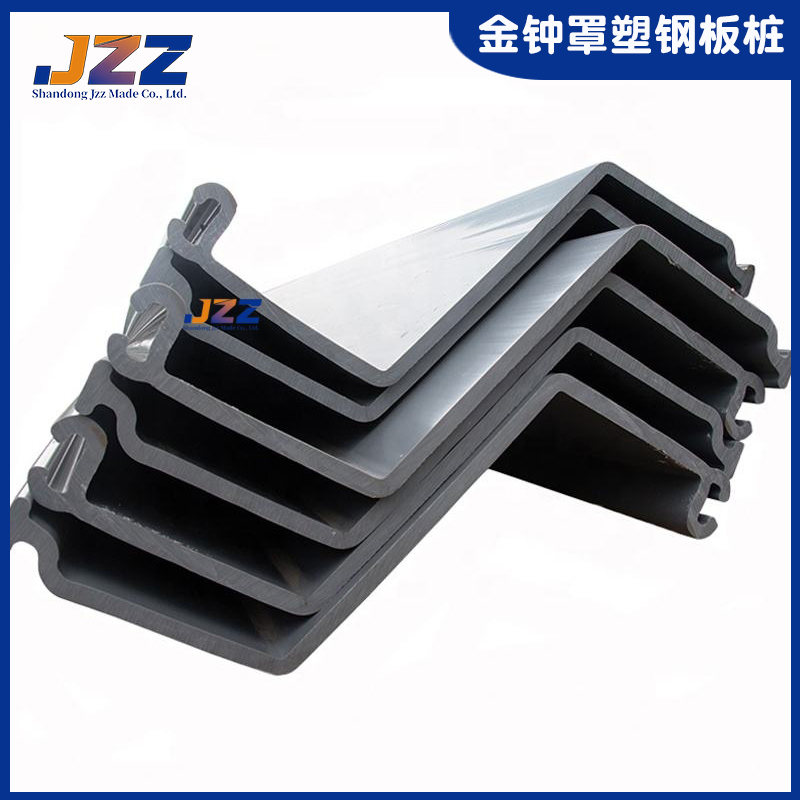

3. Installation Sequence and Techniques Interlock Alignment: Ensure adjacent sheet piles’ interlocks fully engage during installation. Apply lubricant (e.g., silicone grease) beforehand to reduce friction. Segmented Construction: For large-scale projects, install in sections. Inspect overall straightness and interlock sealing every 20-30 meters.

4. Verticality Control Real-time Monitoring: Use a theodolite or level to monitor verticality during installation. Deviation must not exceed 1% (e.g., ≤6cm tilt for a 6-meter sheet pile). Correction Measures: Immediately halt work upon detecting tilt. Correct by adjusting equipment angle or locally excavating soil. Forcibly driving the sheet pile is strictly prohibited.

5. Special Geological Treatment Hard Soil/Rock Layers: Pre-drill holes or use high-pressure water jetting to avoid direct pressure causing sheet pile fracture. Soft Soil Foundations: Install base plates or temporary supports beneath sheet piles to prevent settlement

6. Safety and Environmental Protection Personnel Protection: Operators must maintain distance from vibrating equipment, wear earplugs, and use slip-resistant footwear. Noise Control: In urban areas, prioritize static pressing methods or install sound barriers.

7. Acceptance Criteria • Lock Sealing Integrity: Post-installation, verify lock tightness and inject waterproofing mortar if necessary. • Overall Stability: Validate load-bearing capacity through pull-out tests or horizontal displacement monitoring. For specialized projects (e.g., deep excavations or underwater installations), adjust implementation plans based on specific design requirements.