Mainstream Material Types and Application Key Points:

(I) Mainstream Materials and Core Characteristics

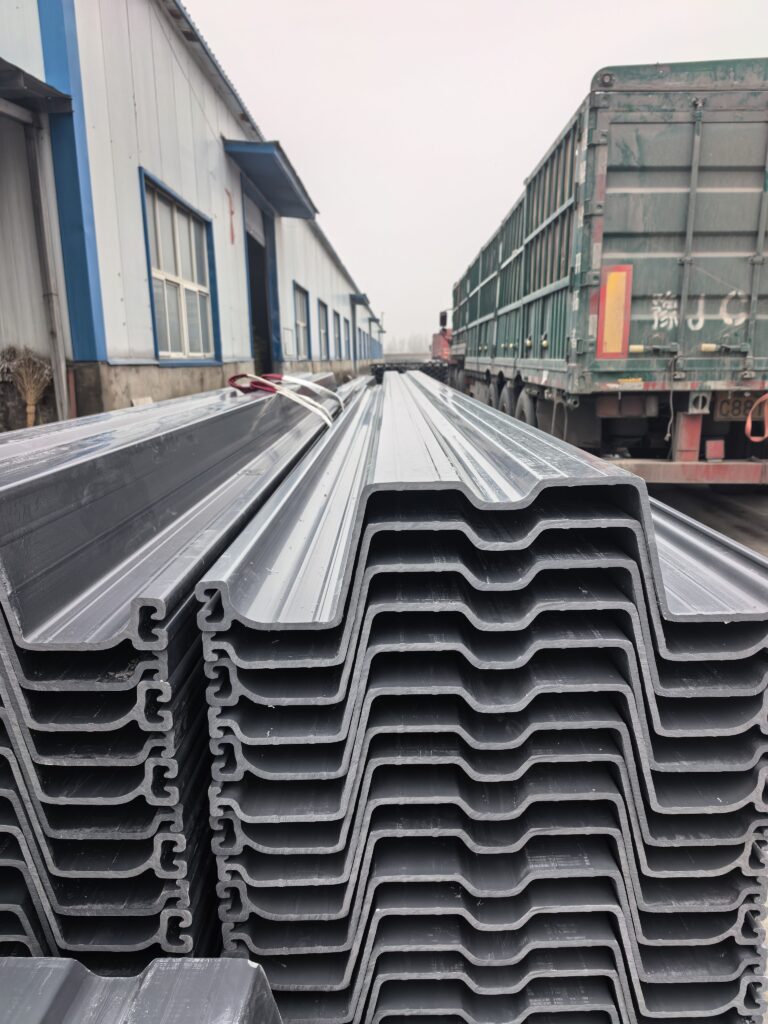

1. High-Strength PVC Sheet Piles: Manufactured from premium polyvinyl chloride as the base material, with added anti-aging agents, impact-resistant modifiers, and other composite components through integrated extrusion molding. Offering exceptional corrosion resistance, lightweight construction, and strong scour resistance, they weigh only 1/4 to 1/6 of steel sheet piles of equivalent specifications. Requiring no heavy lifting equipment, they are suitable for shallow waters, confined spaces, and ecologically sensitive areas. With a service life exceeding 50 years, they are widely used in ecological river channels, urban waterways, and flood control projects in high-rainfall regions.

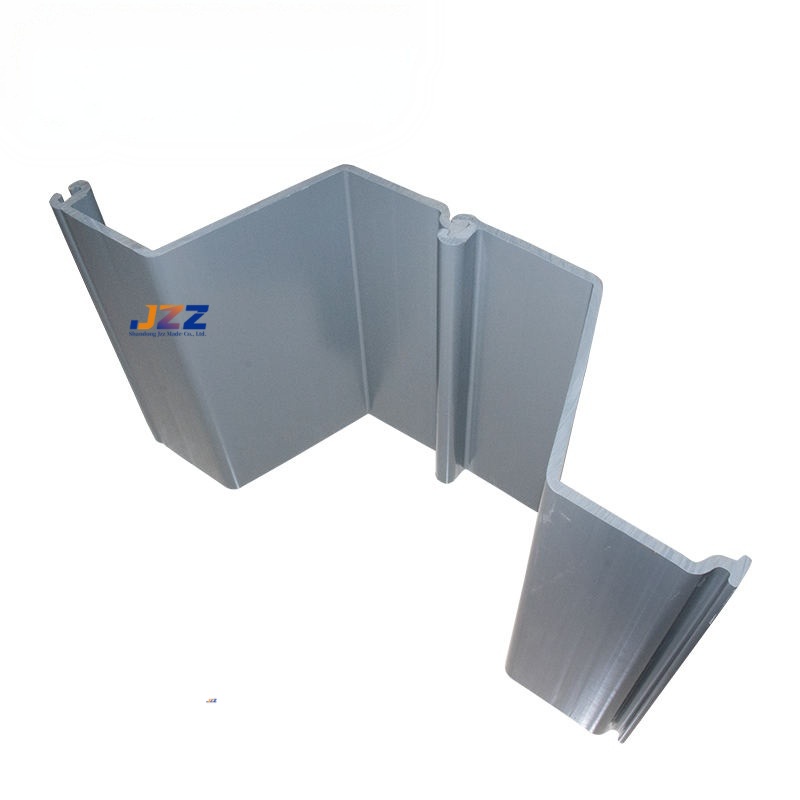

2. Steel-Plastic Composite Sheet Piles: Featuring a composite structure of “plastic anti-corrosion layer + high-strength steel skeleton,” these piles combine the corrosion resistance of plastic with the mechanical strength of steel, delivering outstanding scour resistance and load-bearing performance. The fully encapsulated plastic surface completely isolates corrosive agents, while the inner steel layer provides ample impact resistance. Suitable for high-sediment, high-velocity waterways like flood control projects in the Yellow River basin, it effectively withstands sediment abrasion and hydraulic impact, balancing long-term durability and stability.

3. Corrosion-Resistant Concrete/Mortar: Optimizes concrete microstructure through corrosion-inhibiting admixtures, corrosion-resistant aggregates, or surface coatings, enhancing corrosion resistance and scour resistance. Characterized by high strength, excellent integrity, and moderate cost, it suits embankments, sluice gates, and riverbed protection projects. Suitable for diverse complex aquatic environments, it represents a mainstream upgrade over traditional materials.

4. Polymer Composite Protective Panels: Manufactured from PE and polymer materials, these panels feature smooth, wear-resistant surfaces with outstanding erosion resistance and corrosion resistance. They can be directly laid over existing revetments for reinforcement and repair, offering convenient installation, short construction periods, and lower costs. Suitable for retrofitting aging hydraulic structures and emergency reinforcement scenarios.

(II) Core Application Considerations

1. Precise Material Selection: Scientifically select materials based on river flow velocity, sediment content, water medium, project functionality, and ecological requirements. Steel-plastic composite sheet piles are preferred for high-velocity, high-sediment rivers; high-strength PVC sheet piles (natural-look variants) for ecological rivers; specialized chemical-resistant materials for industrial wastewater rivers; and polymer composite revetment panels for retrofitting aging structures. Ensure materials precisely match performance requirements and operational conditions.

2. Standardized Construction: Strictly adhere to construction technical specifications. Clear debris and underwater obstacles before construction. Conduct precise surveying and layout to control material installation verticality, spacing, and depth. Seal joints and anchor points to enhance impermeability and overall load-bearing capacity. For hard soil layers or complex terrain, employ adapted construction techniques to prevent material damage and ensure construction quality.

3. Post-Construction Maintenance: While erosion-resistant and corrosion-resistant materials require minimal upkeep, regular inspections are essential. Remove accumulated silt, aquatic organisms, and debris from material surfaces. Verify the integrity of joints and interfaces, including sealing and structural soundness. Address any damage or loosening promptly to prevent localized issues from escalating, ensuring long-term stable project operation.